23

Jan, 2016

Earth Island Journal: Amid Farmland, an Oil Field

The Oxnard Oil Field in Ventura County, California doesn’t fit the stereotypical image of an oil patch. There are few pumpjacks bobbing away like in the dusty fields of Kern County, nor any massive open pit mines like those in the tar sands country of Alberta, Canada. Oxnard is better known as the “Strawberry Capital of the World,” and the oil wells and storage tanks there are scattered among the berry fields and rows of broccoli, onions, and tomatoes. By day, farmworkers from Mexico and Central America harvest the crops. At night, oil workers come in and set up stadium lights to work by. The oil production is camouflaged by the farmland, making the tar sands extraction there one of California’s best-kept hydrocarbon secrets.

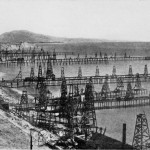

Vaca Energy’s tar sands operation

The oil deposits underneath the farm fields are mostly bitumen – AKA oil sands, AKA tar sands – a mix of clay, sand, water, and petroleum that at room temperature is almost solid. Thinning out and refining such stuff is expensive, and most wildcatters ignore it for other lighter, “sweeter” oil deposits. But when oil hit $100 a barrel seven years ago, some oil companies saw an opportunity and swooped into the area to take over abandoned wells from bankrupted companies. According to the California Division of Oil, Gas, and Geothermal Resources (DOGGR), there are as many as 55 tar sands wells in the area.

The tar sands deposits are extracted via two techniques that are commonly used for accessing other “unconventional” oil deposits. The first is called cyclic steaming, or “huff and puff” in industry-speak. First comes the huff, an underground injection of 10,000 to 20,000 barrels of steaming water shot 2,500 feet underneath the surface, which in the Oxnard area passes through the groundwater table that feeds the municipal water supply. Drillers then install two wells, one of which goes for the deposits. Next comes the puff. A second well nearby uses natural gas to fire up generators to heat the ground to at least 550 degrees Fahrenheit. The steam melts the tar sands so it can come to the surface. The second technique is called steam-assisted gravity drainage (or SAG-D), which has become increasingly common in the tar sands fields of Alberta. SAG-D is a hyped-up version of huff-and-puff that uses multiple steam sessions and hotter temperatures to recover more bitumen.

Read the rest at Earth Island Journal:

You must be logged in to post a comment.